Catalogs

PRODUCTS

Uni-Drive Cardan Shaft Assembly

Uni-Drive Cardan Shaft assembly for Steel Industries, Pulp and Paper Industries, Port Handling and waste-water treatment.

Waste Water Treatment

Waste water treatment and sewage plants. We provide Cardan shaft with Extended length (depend on your requirements) or multiple shaft for a single pump drive for Waste water treatment and sewage plants. Provides Public utilities board (PUB) of Singapore providing them with solution on waste water treatment. We have complete stock of the genuine spare parts here in Singapore to assist you better and faster.

Steel Industries

Requirement in a Steel mill range from Super heavy duty to Medium range cardan shaft. Cardan shaft is a critical power transmission components in a Steel industries. We are able to supply Cardan shaft in different configuration, like:

- Extra long slip movement

- Tunnel Shaft

We are also a leading supplier of Constant Velocity (CV) shaft for special application where Vibration is “NO-NO’ for their production. Industries like:

- Foil roll

- Steel rolls

We constantly stride to work closely with our partner on the ground, providing product training, supervision on installation work and provide site inspection

- Stocking of Genuine spare parts in Singapore means, users have shorter lead time

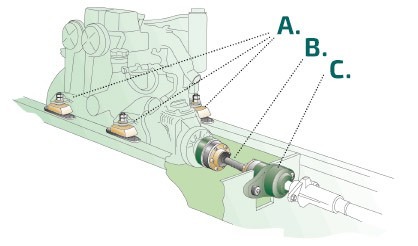

Gallery

Product Showcase

Din Style Shaft

Torque range up to 215,000Nm Flange size ranging from 58mm to 1,200mm Commonly use in European vehicles, steel mills, paper mills, Marine industries, Pumping station All shafts parts are in stock

Sae Style Shaft

Torque range up to 12,000Nm Flange size ranging from 3” to 10” Normally used in American vehicle, Oil and Gas All shafts parts are in stock

Wing Style Shaft

Torque range up to 25,000nm Caterpillar & komatsu trucks and engine.

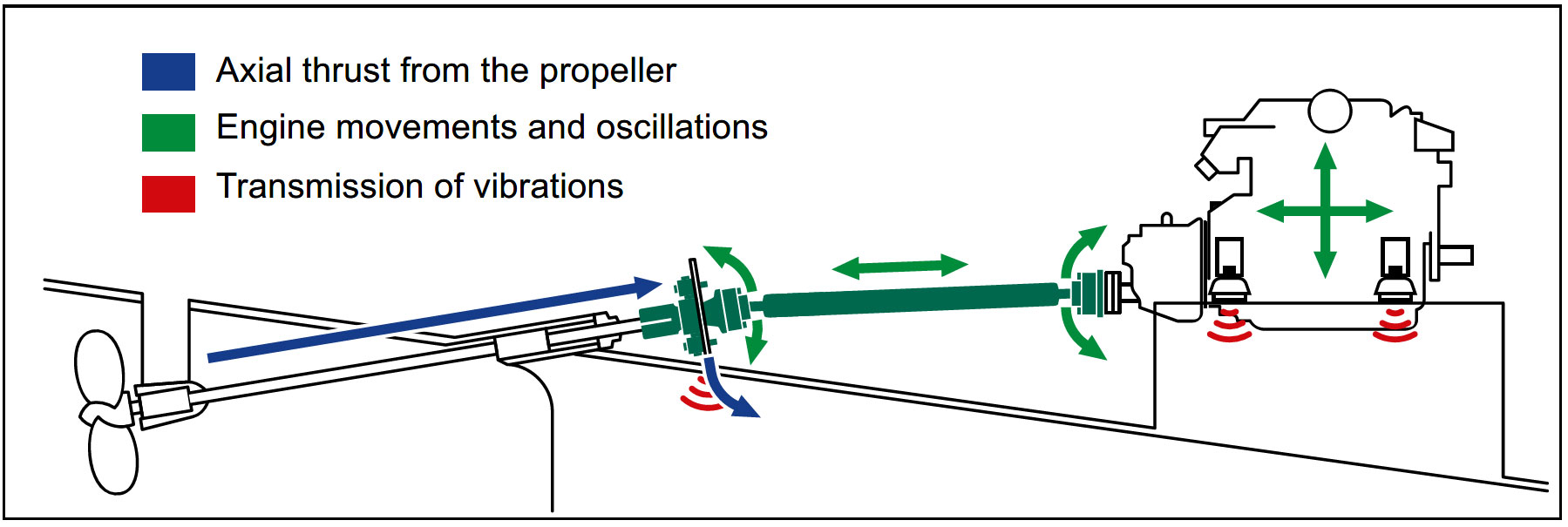

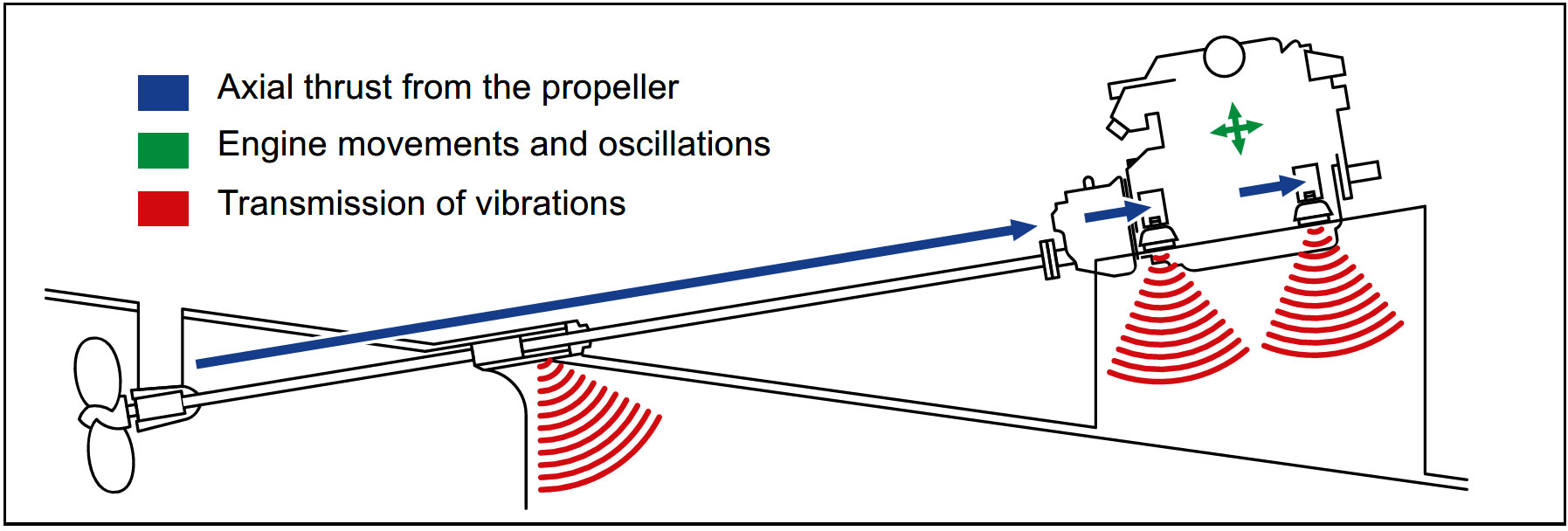

In traditional installations, the alignment of the propeller shaft to the engine has to be precise and subject to periodical maintenance. Stiff mounts transmit high levels of vibration to the hull, even when perfectly aligned.

In traditional installations, the alignment of the propeller shaft to the engine has to be precise and subject to periodical maintenance. Stiff mounts transmit high levels of vibration to the hull, even when perfectly aligned.